Technical principle

Process features

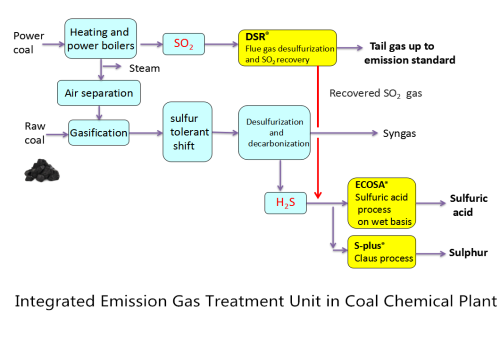

Process route

Project achievement

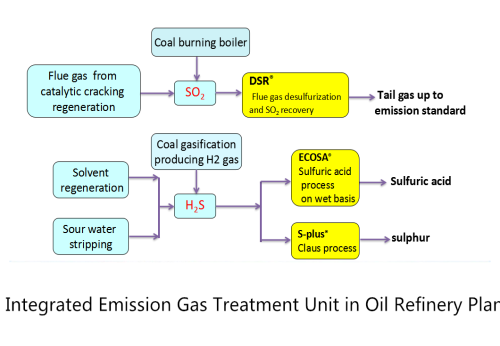

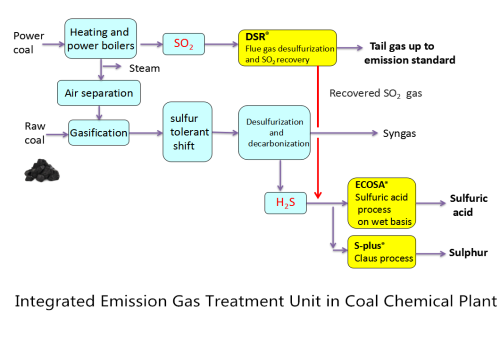

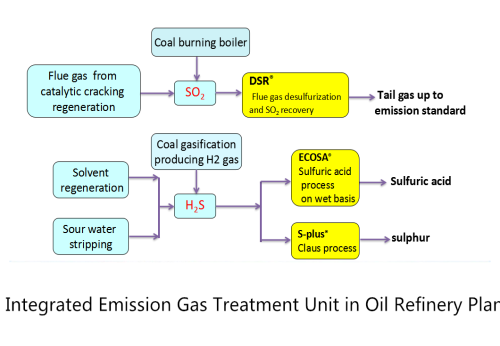

Keyon ECOSA® is a H2S to H2SO4 process on wet basis for sulfur recovery, with authorized patents globally covered and more than 50 reference units. ECOSA can treat H2S containing sour gas or sulfur containing compound discharged from coal chemical plant, oil refinery plant and metallurgical plant etc. ECOSA unit produces sulfuric acid and ensures tail gas meet emission standard. In the meantime, ECOSA unit generates a large amount of steam as by-product.

Process features:

-

Indigenous intellectual property right, so far Keyon Process has more than 29 reference units( 200,000ton/year as the biggest).

-

SO2≤50~100mg/Nm3 in tail gas that meets latest environment protection standard

-

ECOSA unit generates a large amount of steam as by-product, bringing good economic benefit to users.

-

Simple process, compact equipment layout occupies small space.

-

Easy and stable operation, long on-steam period

-

Low CAPEX investment, similar to two stage Claus unit, good price versus performance ratio.

ECOSA® process has developed to a sulfuric acid process on wet baisis that can fully replace similar H2S based wet sulfucric acid process owned by foreign companies.

ECOSA® is a cost effective choice for owner as the investment of ECOSA® unit is similar to the cost of two stage claus unit, and only 50 to 60% of the cost of other WSA unit.

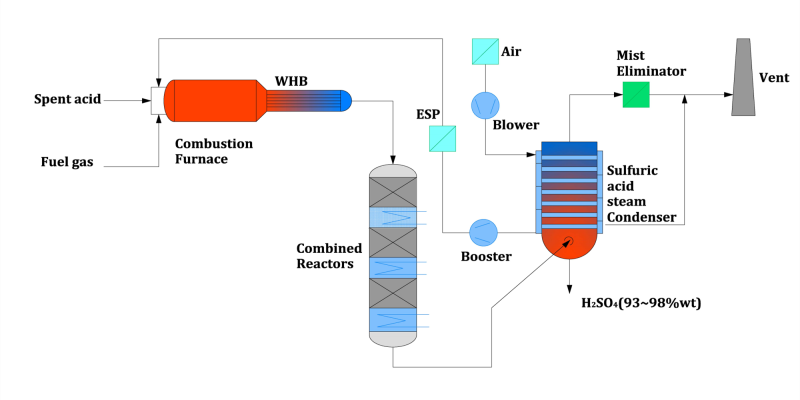

Process route:Process route covers following steps: Sour gas combustion, SO2 catalytic oxidation,

sulfuric acid gas condensation, sulfuric acid cooling and tempering, heat recovery etc.